Silikonowe rękawy cieplne: Niezbędne roztwory do wysokowydajnych zastosowań przemysłowych

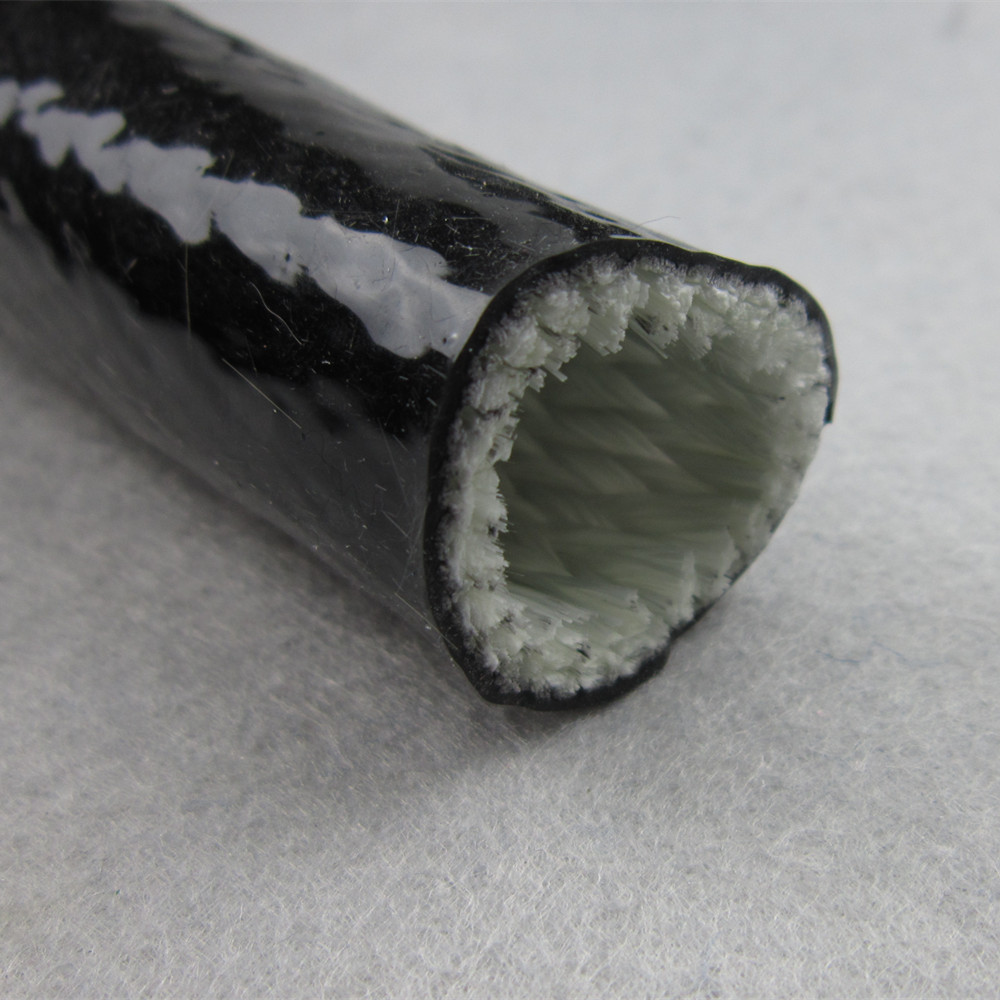

Silikonowy rękaw ciepła jest niezbędnym zasobem w różnych branżach ze względu na ich wszechstronne nieruchomości ochronne, co czyni je wyborem do zabezpieczenia kabli, węży i przewodów w ekstremalnych warunkach Te wysokowydajne rękawy zapewniają niezrównaną odporność na ciepło, ścieranie i ekspozycję chemiczną, zapewniając długotrwałą trwałość i niezawodność

Silikonowe rękawy cieplne są specjalnie zaprojektowane, aby wytrzymać intensywne temperatury, oferując niezawodną ochronę w środowiskach, w których ciepło jest stałym wyzwaniem Niezależnie od tego, czy w wiązce przewodów samochodowych, kablach lotniczych czy maszynach przemysłowych, rękawy te wyróżniają się w oporach do temperatur do 200 ° C Zapewniają krytyczną barierę przed uszkodzeniem związanym z ciepłem, zapobiegając awarii izolacji, szortach elektrycznych lub awarii sprzętu Realne aplikacje obejmują ich zastosowanie w zatokach silników samochodowych, w których zarządzanie ciepłem jest kluczowe, oraz w lotnictwie, gdzie precyzyjna kontrola temperatury zapewnia integralność krytycznych komponentów

W takich branżach, jak konstrukcja i ciężkie maszyny, sprzęt staje w obliczu stałego zużycia Silikonowe rękawy cieplne idealnie nadają się do ochrony węży hydraulicznych i innych istotnych elementów w urządzeniach budowlanych, maszynach wydobywczych i innych stałym zastosowaniach Solidna powłoka zapobiega ścieraniu, przedłużając żywotność węży i kabli narażonych na szorstkie powierzchnie, ostre krawędzie lub środowiska o wysokim zakresie Na przykład w koparce węże hydrauliczne korzystają z rękawów pokrytych silikonem, zapewniając gładkie i ciągłe działanie w trudnych warunkach

Powłoka silikonowa oferuje również zwiększoną odporność na oleje, rozpuszczalniki i łagodne kwasy, zapewniając warstwę ochronną w środowiskach, w których występuje narażenie na substancje korozyjne Ustawienia przemysłowe, takie jak zakłady produkcyjne, obiekty przetwarzania chemicznego lub garaże motoryzacyjne, często obejmują trudne chemikalia, które mogą degradować konwencjonalne materiały Silikonowe rękawy oferują spokój, pilnowanie kabli i węży przed degradacją chemiczną przy jednoczesnym utrzymaniu ich właściwości izolacyjnych i ochronnych Zastosowania w przedziałach silnika, w których występują olej i inne płyny, są doskonałym przykładem tego rękawa ● Odporność

Jedną z kluczowych korzyści z silikonowych rękawów cieplnych jest ich elastyczność i zdolność adaptacyjna w środowiskach dynamicznych, w tym robotyka, automatyzacja i ruchome części maszyn Rękawy utrzymują swoją wydajność nawet pod ciągłym ruchem, wibracją i stresem Na przykład w ramionach robotycznych stosowanych w produkcji okablowanie i kable korzystają z ochrony zapewnianej przez silikonowe rękawy, zapewniając, że ruch nie powoduje uszkodzenia delikatnego okablowania

Przemysł motoryzacyjny: Silikonowe rękawy cieplne są szeroko stosowane w wiązce przewodów samochodowych, aby zapobiec uszkodzeniom cieplnym w temperaturach silnika Ich elastyczność pozwala im dopasować się do złożonych układów kablowych, jednocześnie oferując solidną ochronę przed ścieraniem i ekspozycją chemiczną

Aerospace: W kablach lotniczych, gdzie fluktuacje temperatury i naprężenia mechaniczne są powszechne, rękawy pokryte silikonem zapobiegają awarii elektrycznych i utrzymują integralność okablowania

Ciężki sprzęt: W maszynach budowlanych, takich jak spylacze i dźwigi, silikonowe rękawy są używane do ochrony węży hydraulicznych, zapewniając, że sprzęt działa skutecznie nawet w najtrudniejszych warunkach

Produkcja i robotyka: Rękawy pokryte silikonem zapewniają ochronę w systemach robotycznych ramion i automatyzacji, gdzie stały ruch i narażenie na różne czynniki środowiskowe wymagają materiału, który może się dostosować i znosić

Silikonowe rękawy cieplne są przeznaczone do ekstremalnych środowisk, oferując wyjątkową ochronę przed wysokimi temperaturami, otarciami, chemikaliami i naprężeniami mechanicznymi Dzięki aplikacjom motoryzacyjnym, lotniczym, ciężkim maszynom i robotyce, te wszechstronne rękawy są kluczowym elementem zapewniającym długowieczność i niezawodność kabli, węży i przewodów Niezależnie od tego, czy jest to wrażliwa na ekranowanie elektroniki, czy przedłużenie żywotności układów hydraulicznych, silikonowe rękawy cieplne zapewniają spokój i wydajność niezbędne do sprawnego działania operacji.