Streszczenie: Ten przewodnik pomoże Ci wybrać izolacja wydechu nagrzewnicy diesla I izolacja rury wydechowej nagrzewnicy diesla Do instalacji ogrzewania Webasto, Eberspacher i postojowego. Wyjaśnia tryby ogrzewania, ograniczenia dotyczące prowadzenia przewodów, mocowania i typowe punkty awarii, a także zawiera linki do najodpowiedniejszych produktów BSTFLEX do izolacji wsuwanej i szytej na wymiar.

Dlaczego izolacja jest potrzebna | Jak wybrać | Zasady instalacji | Polecane produkty | Często zadawane pytania

Zarządzanie ciepłem spalin: Rozwiązania izolacji wydechowej | Ochrona węży/przewodów w pobliżu gorących tras: Rękaw ogniowy | Techniczne pliki PDF: Pobierz dokumenty techniczne

Układy wydechowe nagrzewnic Diesla działają w ciasnych przestrzeniach, gdzie ciepło może szybko się gromadzić. izolacja wydechu nagrzewnicy diesla obniża temperaturę powierzchni i promieniowanie cieplne docierające do otaczających paneli, podłóg, okablowania i przewodów paliwowych — zwłaszcza w zamkniętych pomieszczeniach, takich jak kampery, kabiny łodzi, schowki na sprzęt i kanały podwoziowe.

W celu zapewnienia kompleksowej strategii termicznej wielu instalatorów łączy izolację źródła ciepła z ochroną pobliskich przewodów. Jeśli przewody paliwowe lub okablowanie przebiegają w pobliżu wylotu nagrzewnicy, należy zastosować ochrona rękawa ognioodpornego na tych liniach, gdzie było to potrzebne.

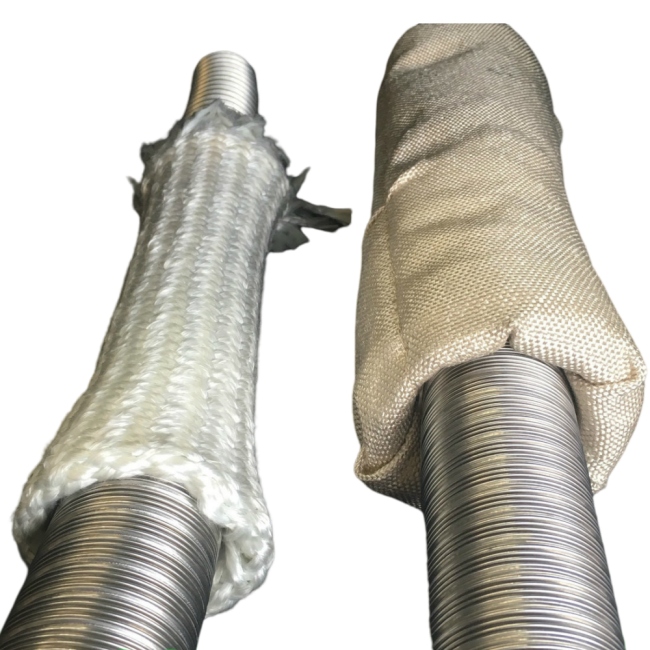

SUGESTIA OBRAZU NR 1

Większość zastosowań można podzielić na następujące kategorie:

Jeżeli Twoje wymagania wykraczają poza ogrzewacze diesla (np. układy wydechowe samochodowe, generatory, układy wydechowe przemysłowe), zapoznaj się z rozwiązania izolacji spalin .

Najczęstszym problemem w terenie jest przesuwanie się izolacji od strefy gorącej z upływem czasu. Zabezpiecz oba końce i sprawdź poprawność prowadzenia po dotarciu. Jeśli posiadasz wsporniki, upewnij się, że izolacja nie przeciera się pod wpływem drgań.

W miejscach, gdzie układ wydechowy przechodzi w pobliżu zacisków, krawędzi cięcia lub wsporników, należy kontrolować punkty styku. W miarę możliwości należy zwiększyć odstęp i upewnić się, że izolacja nie ociera. Jeśli przewody lub przewody paliwowe znajdują się w tym samym miejscu, należy je zabezpieczyć. rękaw ogniowy w strefach krytycznych.

Jeśli izolowany układ wydechowy może stykać się z panelami podczas drgań, należy zaprojektować go tak, aby kontakt ten wystąpił. W miarę możliwości zwiększ odstępy i zastosuj bardziej konserwatywną konstrukcję izolacji.

Sprawdź minimalną odległość podczas rzeczywistej pracy (rozszerzalność cieplna + wibracje). W przypadku ciasnych konstrukcji zdjęcia obszaru prowadzenia przewodów pomogą potwierdzić najlepszą konstrukcję.

SUGESTIA OBRAZU #2

Wybierz strukturę produktu w oparciu o dostęp do instalacji, złożoność routingu i środowisko. Poniższe opcje pokrywają większość potrzeb w zakresie izolacji rur wydechowych w systemach Webasto/Eberspacher/ogrzewaniach postojowych:

W przypadku prostych lub dostępnych odcinków rur, gdzie można nasunąć izolację na wydech, ten styl wsuwany jest praktycznym wyborem:

izolacja wydechu nagrzewnicy diesla

W przypadku skomplikowanych instalacji lub tras, w których ważne jest dopasowanie i mocowanie na miarę, należy wziąć pod uwagę:

wąż wydechowy do nagrzewnicy diesla

Jeśli Twoje wymagania są bardziej ogólne (izolacja rury wydechowej wykraczająca poza izolację nagrzewnic Diesla) lub potrzebujesz wytrzymałej konstrukcji z włókna szklanego:

skarpeta izolacyjna z włókna szklanego

W środowiskach narażonych na ścieranie, zachlapanie lub częste użytkowanie, powlekana struktura może zwiększyć trwałość:

osłona wydechu silikonowa ochronna odporna na wysoką temperaturę

Aby potwierdzić poprawność izolacja rury wydechowej nagrzewnicy diesla Szybko, skopiuj poniższą listę kontrolną do swojego zapytania. Zdjęcia obszaru prowadzenia przewodów są szczególnie zalecane w przypadku ciasnych konstrukcji.

Cel jest podobny – obniżenie temperatury powierzchni i ciepła promieniowania – ale instalacje nagrzewnic wysokoprężnych często znajdują się w ciaśniejszych pomieszczeniach z bardziej rygorystycznymi limitami prześwitu. To sprawia, że retencja, kontrola ścieralności i walidacja prześwitu są ważniejsze.

Osłona termiczna chroni sąsiednie elementy przed promieniowaniem cieplnym, a izolacja redukuje ciepło u źródła. W przypadku szczelnych konstrukcji izolacja rury często zapewnia bardziej spójne rezultaty, a osłonę można dodać tam, gdzie sąsiednie elementy nadal wymagają ochrony.

Izolacja przesuwa się, luzuje lub przeciera na wspornikach/zaciskach pod wpływem wibracji. Zabezpiecz oba końce, skontroluj punkty ścierania i sprawdź luz przy pełnym obciążeniu.

Tak. Konstrukcje łodzi i kamperów zazwyczaj mają zamknięte komory, w których stosuje się izolację spalin z nagrzewnicy diesla, aby zmniejszyć narażenie na ciepło. Prosimy o podanie ograniczeń trasy i otoczenia, abyśmy mogli polecić najlepszą konstrukcję.

Jeżeli przewody paliwowe lub okablowanie przebiegają w pobliżu wylotu nagrzewnicy, należy zastosować specjalne zabezpieczenie, np. rękaw ogniowy Jest to szczególnie ważne w miejscach o ciasnym prześwicie oraz wokół zacisków i wsporników.

Tak. Wiele arkuszy danych i technicznych plików PDF jest dostępnych w Pobierz dokumenty techniczne Jeśli potrzebujesz pakietu dokumentów do zatwierdzenia (CoC lub protokoły z inspekcji, jeśli ma to zastosowanie), poproś o niego za pomocą formularza wyceny.

Podziel się średnicą zewnętrzną rury wydechowej, jej długością, prześwitem, środowiskiem (kamper/łódź/podwozie/szafka) oraz zdjęciami miejsca montażu. Zaproponujemy praktyczną konstrukcję izolacji i potwierdzimy najlepszą opcję produktu dla Twojej instalacji.